At the Airbus Summit 2025 stand dedicated to "UpNext" projects, a mysterious miniature Cessna Citation VII stood proudly on its base, accompanied by a television screen broadcasting a continuous report. In the footage, a mechanic equipped with an angle grinder was busy following a line formed by a laser beam, cutting the entire wing from its junction with the fuselage. Despite the precision work, everything looked handcrafted. "Even the music for the report was composed by a colleague," smiled an Airbus manager, watching the images.

This work by a small team dedicated to the aircraft manufacturer's future technologies took place at the Cazaux military base, near Bordeaux. Its engineers are actively preparing the integration of their eXtra Performance Wing, a unique folding wing with a very special hinge. A new design, and a new approach for aeronautics, where the hinge will fold the wing when the aircraft taxis on the tarmac, then unfold it when it's time to take off. A joint that will also play a role in flight, to improve the aerodynamic efficiency of the aircraft, similar to the behavior of albatrosses.

The project is not new. In 2019, it involved the design of AlbatrossOne, a reduced-scale A321 demonstrator with "free-flapping" wings. Inspired by the bird with the largest wingspan in the world, Airbus noted that by increasing the dimensions of its aircraft's wings, it could reduce their drag, kerosene consumption, and therefore CO2 emissions. The outgrowth would also reduce the risk of stalling on landing. The problem is that to accommodate aircraft with larger wings on airport grounds, it will not be possible to modify the infrastructure. The only solution is to fold the wings at their tips.

A first unmanned test flight over the Atlantic

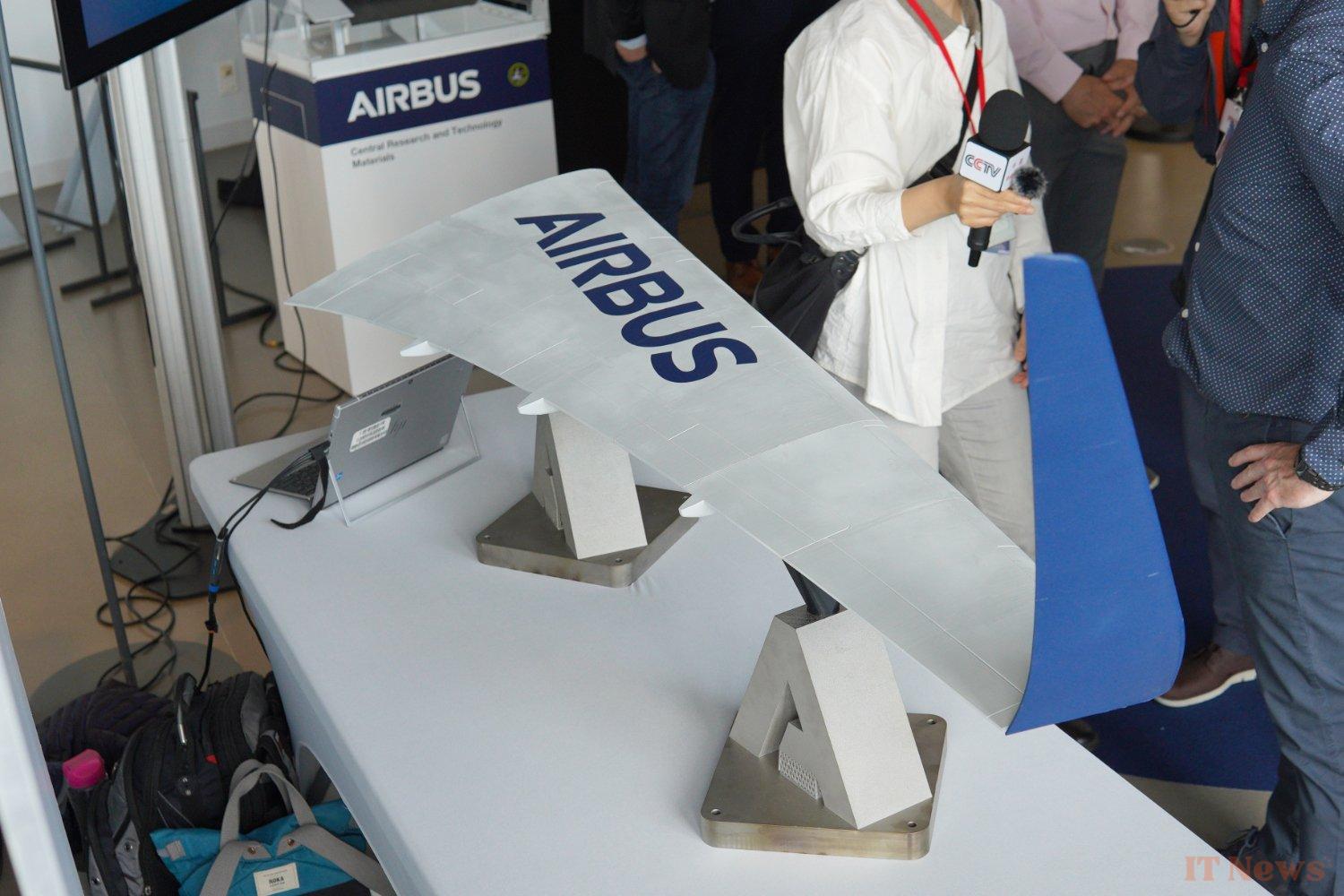

The aircraft in question, on which Airbus's UpNext teams cut the wings, is a Cessna Citation VII. A private jet that will bring us closer to the goal of equipping the new folding wings on the future generation of A320s. The size of the demonstrator allows for the integration of wings at a scale of 1/3 compared to what will be on the future single-aisle airliner. In Toulouse, Airbus gave us the opportunity to approach the tip of the wing that will fold, but forbade us from taking a look at the hinge. It is through this system that Airbus will bring together all its technologies.

"This is the one that required a lot of research, to determine whether to choose hydraulic or electric controls. Its design must also meet resistance standards," the speaker explained to 01net.

The first test flight will be carried out from Cazaux, in May 2026. The aircraft will take off over the Atlantic, in airspace generally reserved for Army tests. "For the first time, we will test it in flight. As we will push our technologies to their limits, we will have no one on board. The aircraft will be remote-controlled and we will fly over the Atlantic. We will not risk injuring anyone in the aircraft or on the ground. As it is a model from the 70s, with mechanical controls, we are in the process of transforming it to Airbus standards, with electric controls that will respond to ground commands in less than 200 milliseconds," he explained.

The flight test will not only focus on takeoff and landing. By flying over the Atlantic, Airbus also aims to test several configurations for its wings, by modifying the hinge angle. This will allow us to measure how the aircraft will respond. A phase is even planned in which the hinge will offer no resistance and will allow the complete wing to position itself as it wishes, depending on the lift.

Another revolution in ailerons

The Airbus video dates back to November of last year, and the wing cutting scene took place a month earlier, in October. The engineers therefore still have time before embarking on the first test flight. A period which will also serve to integrate – or not – other innovations. Among them, the UpNext team presented at the Airbus Summit 2025 with a new approach to ailerons. Rather than fixed parts modifying their degree of inclination by means of hydraulic systems, the ailerons of tomorrow could be designed in a flexible material which can bend. A system that will refine the final design and lighten it.

Wing composition is another project to which Airbus has dedicated a special team, alongside that of UpNext. Grouped behind the "Wing of Tomorrow" program, it is led by Sue Partridge, also head of the Airbus Commercial Aircraft division in the United Kingdom. After focusing on the design of the A380 wings and the A320neo and A330neo programs, the engineer is now imagining the design and components of the wings of tomorrow. At the Airbus Summit 2025, the focus was on promoting composite, a new ultra-light alloy made of CFRP, a carbon fiber reinforced polymer.

The challenge with this composite will be to expand its use to larger-scale production, such as the A320 family. On the wings of the A350 and those of the A220 (with Spirit Aerosystems), Airbus has already integrated its latest innovations. But the process will be difficult to integrate on aircraft productions of double-digit per month, in other words single-aisle aircraft. Folding wings could, however, simplify the system by reducing the size of the ovens needed for "curing," called "autoclaves."

0 Comments